[Material Info]Elements of Butt Welding of Titanium Steel Clad Plates

2024.07.16

1.Abstract

Titanium/Steel clad plate is an advanced metal with layered composite material which is composed of titanium plate and steel plate in a layered manner. It combines the excellent corrosion resistance of titanium with the high strength and low cost of steel. It is widely used in Petrochemical, Power, Salt chemical, Transportation, Desalination, and Marine industries. As the application fields of titanium/steel composite plates continue to expand, the correct welding of titanium steel clad plates directly affects the service life of the equipment in complex working conditions in the later period. This article explains the following points on how to weld titanium steel clad plates.

2.Welding Method

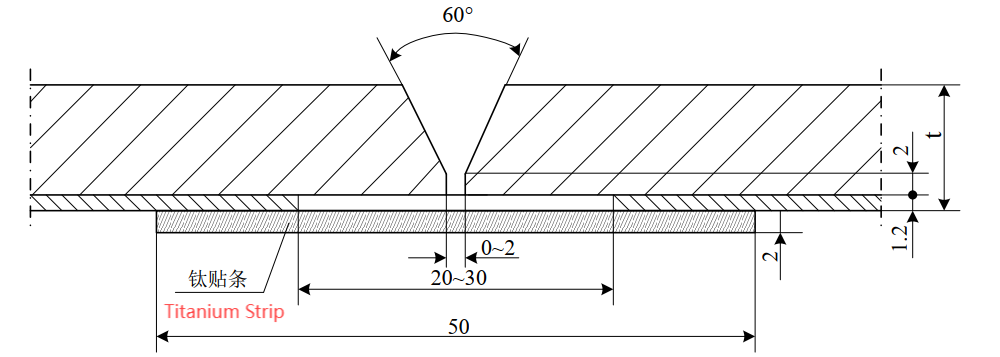

2.1 Bevel Form

2.2 Welding Sequence

Weld seams and their surroundings should be cleaned around 200mm Positioning Welding

Positioning Welding Base layer welding

Base layer welding Strip welding

Strip welding

2.3 Welding Precautions

2.3.1 The welding environment should be kept clean, free of moisture and pollutants, the relative humidity should not be greater than 80%, and the temperature should not be lower than 15℃ within 100mm around the weld.

2.3.2 Low current welding should be used for base welding to prevent excessive heat from causing oxidation of the titanium surface and uneven separation of the titanium layer. The optimal interlayer temperature should be controlled below 150 ℃.

3.3.3 The surface of the welding wire, groove surface and the 20mm area in between should be cleaned. No forced assembly is allowed, and the positioning weld seams must not have cracks, pores, slag inclusions and other defects. The number of weld repairs in the same part shall not exceed 2 times, and penetration (PT) testing shall be used.

2.3.4 Welding personnel must undergo professional training, pass the examination and get the certification. Please refer to Appendix A of GB/T13149 for specific requirements.